Barcode Manufacturing

BARCODE MANUFACTURING

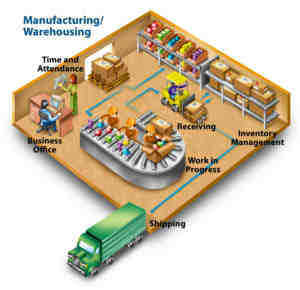

For manufacturing companies, inventory transaction occurs in every area. Starting from customer orders to purchase orders to manufacturing orders, each order consists of multiple stock in/out records. A simple and reliable inventory system is needed to automate all these transactions.

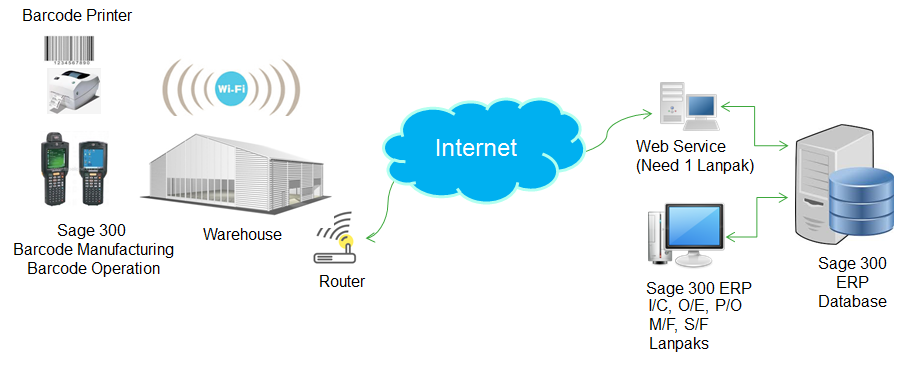

With Barcode Manufacturing (B/M) all the material issue, material return, and finished goods receipt could now be recorded by handhelds and updated online with the backend Sage 300 ERP system.

- Improve Accuracy of Raw Material usage and finished goods receipt entry.

- Increase Efficiency by reducing manual data entry.

- Enhance Productivity, Minimize inventory (carrying cost), Maximize profits.

- Increase Customer Service & Satisfaction.

MO Material Issue

Once Manufacturing Order has been released, material issues could be recorded by the barcode scanner by scanning the item barcode and issued quantity with selected manufacturing order.

MO Material Return

Material return could be recorded by scanning the item barcode and issued quantity with selected manufacturing order.

MO FINISHED GOODS RECEIPT

- Support Backflush Receipt & Issuance

- Support Kanban Processing (JIT)

- Security by User ID, Handheld and Warehouse

- Support Lot/Serialized Number

- Lot/Serial tracking requires Sage 300 Lot/Serial module together with Manufacturing Lot (M/L)